The Plating and Coating eBook

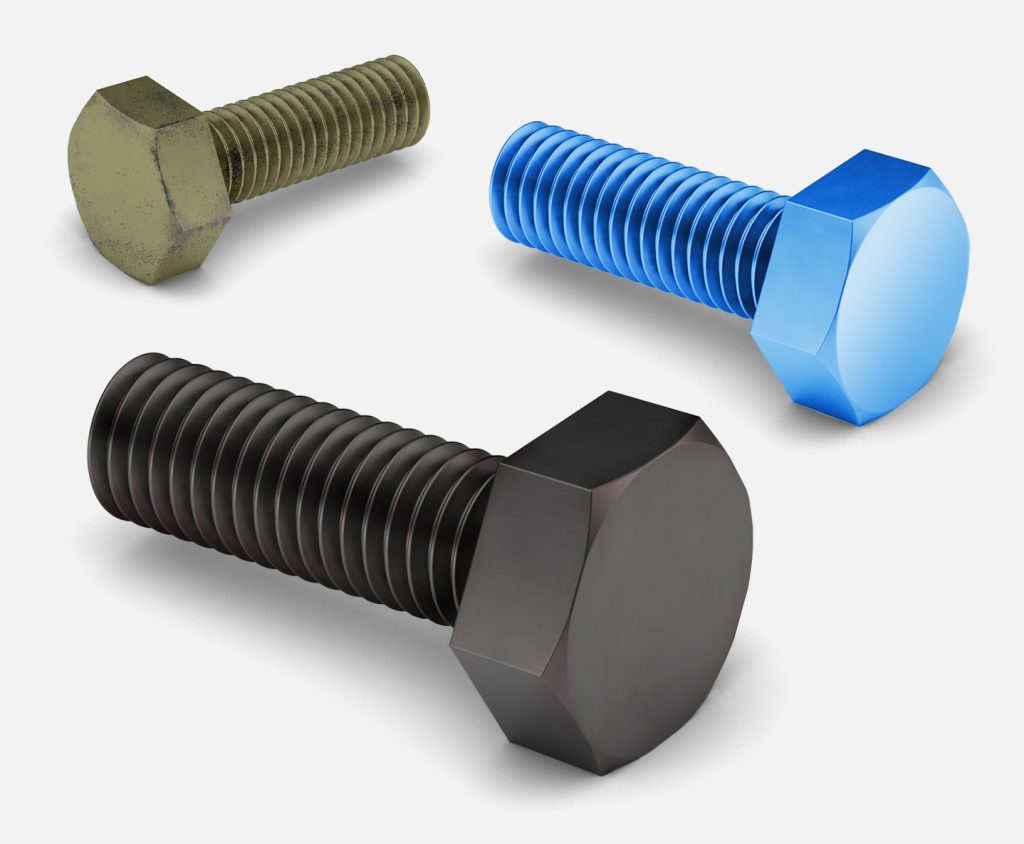

Protecting Industrial Fasteners from Corrosion and Other Harsh Environments.

Here at Earnest Machine, we understand the problems that corrosion, chemical exposure, and harsh environments can bring to fasteners used in industrial applications.

As a company centered around helping its customers succeed, preventing these issues is a big part of what we do.

Corrosion and wear are the greatest enemies to fasteners. Once corrosion begins, fasteners start to break down quickly, reducing their effectiveness and lifespan on any application. Fasteners made from carbon or high strength alloy steels, that are subjected to harsh environments or hazardous chemicals, typically have a plating or coating applied to their surface to protect the steel underneath. Fasteners that lack this protective layer can become damaged, ultimately compromising their assembly, which can be both dangerous and costly to replace.

The solution is simple:

plating or coating fasteners with a protective layer.

plating or coating fasteners with a protective layer.

This eBook will provide a background on the plating and coating processes, the wide range of options available within each category and how to specify the properties needed for each application.

Topics include:

The difference between plating and coating

The importance of salt spray testing

Plating styles

Coating styles

Sourcing specifications and suppliers

Three tips for selecting plating and coating options

Download your free copy of our plating and coating eBook